Biochar Trench

The cheapest, easiest way for small farmers across the developing world to make biochar from crop waste and why it is important that they do

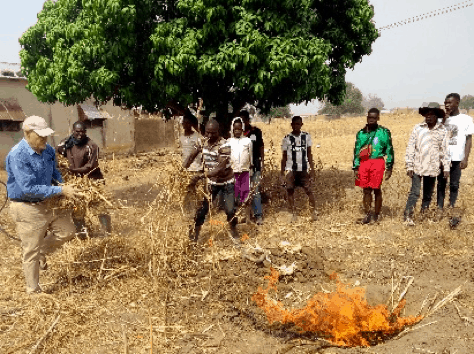

Standard operating procedure: burning crop waste

Small farmers in the developing world burn 21 gigatons of crop waste annually. Burning just half of this waste adds 16.6 gigatons of eCO2 to the atmosphere and emitting billions more of tonnes of black carbon, smog precursors and PM 2.5, while destroying one of their only valuable agricultural resources.

Few have tried to offer solutions to this problem and no viable solutions are in place for two reasons. The wide dispersion of tiny amounts of crop waste among 2.5 billion small farms renders large-scale, centralizing solutions uneconomical; efforts to “educate” fringe farmers about the need to stop burning generate steadfast resistance by farmers who have no choice but to burn.

Few have tried to offer solutions to this problem and no viable solutions are in place for two reasons. The wide dispersion of tiny amounts of crop waste among 2.5 billion small farms renders large-scale, centralizing solutions uneconomical; efforts to “educate” fringe farmers about the need to stop burning generate steadfast resistance by farmers who have no choice but to burn.

Mr. Bic is every poor farmer’s best friend

What can work

Very small-scale, very low-cost, very low-tech, in-field conversion of crop waste to biochar by farmers offers a solution for everyone. Charring eliminates eCO2, black carbon, smog precursor and PM 2.5 emissions, and biochar used as a soil amendment sequesters CO2 at a ratio of three parts CO2 per part of biochar, all of which makes globalists happy.

Poor farmers are also delighted to make and use biochar because production is easy, cheap and requires little time or effort, while the biochar replaces costly synthetic fertilizers, restores degraded soils, improves water penetration and retention, raises pH, increases fertility and vitalizes soil life.[1]

Poor farmers are also delighted to make and use biochar because production is easy, cheap and requires little time or effort, while the biochar replaces costly synthetic fertilizers, restores degraded soils, improves water penetration and retention, raises pH, increases fertility and vitalizes soil life.[1]

Using a biochar trench to make char on the farm: How it Works

|

Trench and roofing sheet

|

What is the secret?

The trench. Literally, a short trench dug by hand in the ground combined with a sheet of roofing metal. The only material required is a common sheet of zinc’ed, corrugated roofing metal (normally about 1.8 or 2 meters (m) long and 50 to 70 centimeters (cm) wide). It can be new or old (as long as it does not have large holes in the middle). Such sheets are ubiquitous in the developing world.[2]

|

The farmer digs a trench in the ground that is 70 cm deep, slightly shorter and slightly less wide than the roofing sheet, and slopes in slightly from the top edges to the bottom. (S)he digs this trench next to the pile of rice straw or a pile of whatever biomass (s)he wants to use.[3]

The farmer starts a fire at the bottom of the trench and once it is established, begins throwing in crop waste. (S)he should throw it in loose, not in large bundles, so that the fire does not smoke a lot, but should resist making a bonfire as this will result in the combustion of lots of valuable carbon, reducing the biochar yield.

The fire is kept going until the trench is completely full of char. (With a standard trench and ready crop waste, this can take as little as ten minutes.)

The farmer then slides the roofing sheet over the trench to close it and seals the edges with the loose dirt from digging the trench, stamping it down to make a good closure. When (s)he is done, (s)he inspects to make sure that no smoke is escaping. If (s)he sees smoke, (s)he needs to close the vent with more dirt.

The farmer starts a fire at the bottom of the trench and once it is established, begins throwing in crop waste. (S)he should throw it in loose, not in large bundles, so that the fire does not smoke a lot, but should resist making a bonfire as this will result in the combustion of lots of valuable carbon, reducing the biochar yield.

The fire is kept going until the trench is completely full of char. (With a standard trench and ready crop waste, this can take as little as ten minutes.)

The farmer then slides the roofing sheet over the trench to close it and seals the edges with the loose dirt from digging the trench, stamping it down to make a good closure. When (s)he is done, (s)he inspects to make sure that no smoke is escaping. If (s)he sees smoke, (s)he needs to close the vent with more dirt.

The majority of farmers do not have water in their fields during the dry season when they make biochar; we have designed the roofing sheet smothering system for them. If a farmer has water, (s)he can quench rapidly with water. If it is necessary to smother as described here, the process is long – it takes about 5 hours for the char to go out.

If the farmer is smothering, we suggest that (s)he prepare a lot of trenches in advance – 10 or 15 – because they can be filled so fast. (The farmer can increase the amount of char produced per trench from hays, stalks and straws by using a stick to crumble the accumulating char. It will break up easily and pack well. Even with such low density feed stocks, a trench yield up to 5 kg of char.) Trench char requires no drying or grinding and is in the field where needed. (see The Paga Biochar Project in Ghana)

If the farmer is smothering, we suggest that (s)he prepare a lot of trenches in advance – 10 or 15 – because they can be filled so fast. (The farmer can increase the amount of char produced per trench from hays, stalks and straws by using a stick to crumble the accumulating char. It will break up easily and pack well. Even with such low density feed stocks, a trench yield up to 5 kg of char.) Trench char requires no drying or grinding and is in the field where needed. (see The Paga Biochar Project in Ghana)

How much char can a farmer get?

In a world of synthetic fertilizers custom tailored to specific soils, crops and weather conditions, it is easy to forget just how few options most poor farmers’ have. Despite all the hype, many have no access to synthetic fertilizers, cannot afford them, or do not know how to use them.

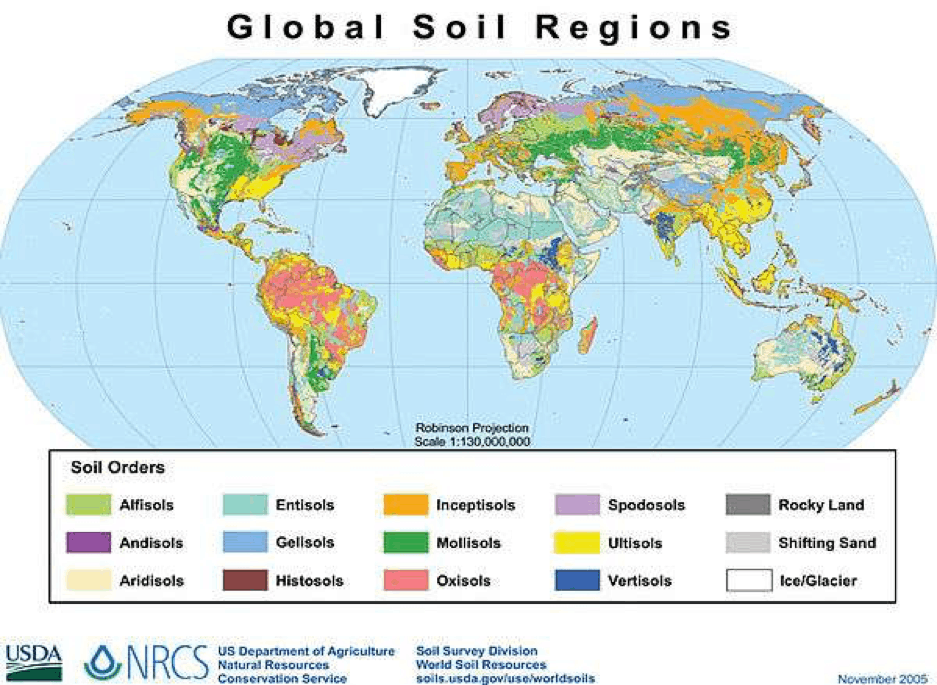

No less important, in a world of well-tended soils, it is easy to forget that much of the soil in the developing world is Ultisols and associated types (Acrisols, Oxisols, Alisols, Nitisols and Retisols) (The names vary by national and international naming organization.).[4] Those in the Ultisol-Acrisol-Oxisol-Alisol-Nitisol line are often deemed infertile because they are too acid (pH 4-4.5), too hard, and/or too dead – conditions that fertilizers cannot treat (and may aggravate).

No less important, in a world of well-tended soils, it is easy to forget that much of the soil in the developing world is Ultisols and associated types (Acrisols, Oxisols, Alisols, Nitisols and Retisols) (The names vary by national and international naming organization.).[4] Those in the Ultisol-Acrisol-Oxisol-Alisol-Nitisol line are often deemed infertile because they are too acid (pH 4-4.5), too hard, and/or too dead – conditions that fertilizers cannot treat (and may aggravate).

For poor farmers with no alternatives, biochar looks great. It increases porosity, retains water, raises pH as much as a full unit, holds nutrients, improves soil’s capacity to exchange nutrients and vitalizes soil life. But can farmers make enough biochar from crop waste to make a difference? The short answer is yes; a sufficient answer requires more.

How much biochar a farmer can produce depends on how much waste (s)he produces and how efficient the biochar making technology is. The trench is not the most efficient of homemade technologies. It may reach a conversion rate of 20%, while TLUDs can reach 30%. How much waste there is depends on the yield and the crop – corn/maize is hugely wasteful, rice less so. A poor crop does not produce as much waste as a good one; poor farmers produce less waste than rich ones.

How much biochar a farmer can produce depends on how much waste (s)he produces and how efficient the biochar making technology is. The trench is not the most efficient of homemade technologies. It may reach a conversion rate of 20%, while TLUDs can reach 30%. How much waste there is depends on the yield and the crop – corn/maize is hugely wasteful, rice less so. A poor crop does not produce as much waste as a good one; poor farmers produce less waste than rich ones.

Does low dose biochar make a difference?

What does this mean in practical terms? If farmers are growing paddy, the amount of straw that they produce will not normally produce “enough” biochar to fully treat their soil if we use the developed world standard of 10 tonnes per hectare (ha) or 1 kilogram (kg) per square meter (m2).

This amount, however, may be meaningless in the developing world. In Warm Heart’s experience, there seems to be an inverse relationship between the quality of soil and the required amount of biochar. That is, the better the soil (the developed world case), the more biochar is needed; the worse the soil (the developing world case), the less biochar is needed.

At Warm Heart, we have observed this first hand in North Thailand where we work. Here rice yields are extremely low, the soil is poor (pH 4.5, no cultivable soil life) and therefore rice straw yields are extremely low. By our calculations, at a conversion rate of 25%, the straw from an average North Thai rice paddy will produce the equivalent of 125 grams (g) of biochar per m2 or one eighth of the recommended amount.

Has this led us to give up?

Not at all.

This amount, however, may be meaningless in the developing world. In Warm Heart’s experience, there seems to be an inverse relationship between the quality of soil and the required amount of biochar. That is, the better the soil (the developed world case), the more biochar is needed; the worse the soil (the developing world case), the less biochar is needed.

At Warm Heart, we have observed this first hand in North Thailand where we work. Here rice yields are extremely low, the soil is poor (pH 4.5, no cultivable soil life) and therefore rice straw yields are extremely low. By our calculations, at a conversion rate of 25%, the straw from an average North Thai rice paddy will produce the equivalent of 125 grams (g) of biochar per m2 or one eighth of the recommended amount.

Has this led us to give up?

Not at all.

Experimental Test Farm

It is also never “used up”, but rather remains forever in the soil improving in quality for at least its first four years in residence. That is to say, if a farmer plows the char made from the straw of a paddy back into the mud for eight years, the result will still be 1 kg per m2. In our experience, achieving this goal in unnecessary.

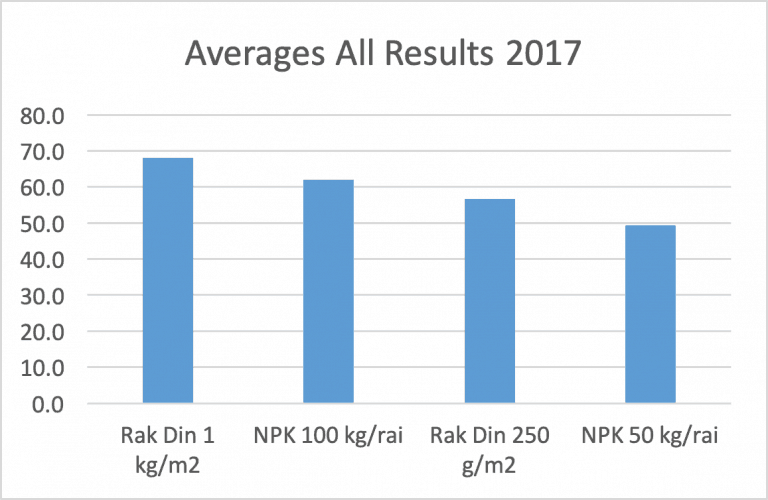

In experiments conducted over four years (so far) at our Experimental Farm, biochar fertilizer has performed well. (“Rak Din” is the name of the Warm Heart social enterprise that buys farmers’ biochar and produces biochar-based products to make a market.)

Used at a full kg per m2, biochar-based fertilizer always performed as well as or outperformed NPK fertilizer applied at a rate of .0625 kg per m2 (625 kg per ha, wealthy farmers’ application rate).

At 250 g per m2 (one quarter application) biochar based fertilizer performed slightly less well than NPK fertilizer at this application, but outperformed NPK applied at one half this rate (312.5 kg per ha or less is regular farmers’ application rate). (Paired comparisons not statistically significant.)

To test biochar fertilizer as actually made and used by farmers, Warm Heart took its experiments to farmers. Here we asked farmers to make their own biochar and biochar fertilizer and to apply it.

The experiment called for farmers in two sub districts separated by 30 kilometers to select two rice paddies located immediately next to each other that had always yielded equally and lay adjacent to a well traffic road.

In experiments conducted over four years (so far) at our Experimental Farm, biochar fertilizer has performed well. (“Rak Din” is the name of the Warm Heart social enterprise that buys farmers’ biochar and produces biochar-based products to make a market.)

Used at a full kg per m2, biochar-based fertilizer always performed as well as or outperformed NPK fertilizer applied at a rate of .0625 kg per m2 (625 kg per ha, wealthy farmers’ application rate).

At 250 g per m2 (one quarter application) biochar based fertilizer performed slightly less well than NPK fertilizer at this application, but outperformed NPK applied at one half this rate (312.5 kg per ha or less is regular farmers’ application rate). (Paired comparisons not statistically significant.)

To test biochar fertilizer as actually made and used by farmers, Warm Heart took its experiments to farmers. Here we asked farmers to make their own biochar and biochar fertilizer and to apply it.

The experiment called for farmers in two sub districts separated by 30 kilometers to select two rice paddies located immediately next to each other that had always yielded equally and lay adjacent to a well traffic road.

The farmers were instructed to apply the biochar fertilizer to one paddy and their preferred mix of NPK to the other. They were then told to treat the two paddies exactly the same.

The farmers gave us their impressions of season, the two paddies were harvested separately on the same day and the yields compared. After the harvest we interviewed the farmers on video about the experience.

Using 1 kg per m2, these farmers increased their paddy yields 10.8% above those of NPK fertilized paddies.[5]

Even better, this was not what impressed them most about using biochar. It actually ranked third behind the improvement in the quality of their soil (they all reported happily, “the worms came back”) and the improved health of their plants. (Farmers selected to test biochar at 250 g per m2 dropped out of the project for reasons unrelated to biochar.)

The farmers gave us their impressions of season, the two paddies were harvested separately on the same day and the yields compared. After the harvest we interviewed the farmers on video about the experience.

Using 1 kg per m2, these farmers increased their paddy yields 10.8% above those of NPK fertilized paddies.[5]

Even better, this was not what impressed them most about using biochar. It actually ranked third behind the improvement in the quality of their soil (they all reported happily, “the worms came back”) and the improved health of their plants. (Farmers selected to test biochar at 250 g per m2 dropped out of the project for reasons unrelated to biochar.)

Remember two more things: (1) biochar never goes away. Even if farmers add only 125 g/year, in 8 years, they will be at the magic 1 kg/m2. (2) Biochar binds NPK such that even a small amount of biochar in a field will dramatically improve the performance of any synthetics a farmer uses by preventing leaching. (The literature suggests that because 50% of NPK leaches with the first rains, farmers using biochar can cut NPK applications by half and get the same performance – a big input cost saving!)

|

Remember, too, that most farmers in the developing world plant by hand and not by tractor.

This fundamentally changes the calculation of how much biochar is required in a field, as well as expectations of how much impact it will have. A square meter is 10,000 square centimeters that, in the developed world, in principle, would each get 0.1 grams of biochar when plowed in (1,000 g / 10,000 cm2 = 0.01 g/cm2). |

Spreading Biochar by tractor

|

|

Where a farmer is planting by stick, however, (s)he will make a hole that is 25 cm x 25 cm (625 square centimeters) every 30 centimeters on rows that are 30 to 40 centimeters apart.

This will yield 9 to 12 holes of 625 cm2 or no more than 7,500 cm2, three quarters of a square meter. Furthermore, rather than spreading his/her char thinly across a considerable area that will grow nothing but weeds, the farmer places it only where immediately accessible to the plants. In effect, the method of planting reduces the biochar required by 25% and makes the biochar supplied more useful. |

One bag of biochar,

one bag of seeds |

Prepared hole

|

Why the rest of us might care

Small farmer crop waste burning in the developing world should concern the 20% of the world’s population living in developed countries to the extent that they are concerned about global warming and climate change.

The amounts of eCO2 emitted are huge. The more crop waste converted to biochar, the less eCO2 emitted and the more CO2 permanently sequestered, the less CO2 in the atmosphere. (The other consequences of crop waste burning affect only the developing world and so are of only indirect concern to the developed world.

The one potential indirect concern – large-scale hunger – connects only partially to biochar and is too far off to fall within the realm of political consideration, despite populist concerns about immigration.

The amounts of eCO2 emitted are huge. The more crop waste converted to biochar, the less eCO2 emitted and the more CO2 permanently sequestered, the less CO2 in the atmosphere. (The other consequences of crop waste burning affect only the developing world and so are of only indirect concern to the developed world.

The one potential indirect concern – large-scale hunger – connects only partially to biochar and is too far off to fall within the realm of political consideration, despite populist concerns about immigration.

[1] Where farmers cultivate land contaminated by industrial chemicals, landfill leachates, mine wastes, pesticide residues or heavy metals, biochar prevents plants from taking up toxins, reducing danger to the food chain.

[2] This system has been tested by Warm Heart at our home facility and in Thai mountain corn fields. In December 2018 the director tested the system in North Ghana with subsistence farmers charring millet stalks. The trench did not smoke and ran at an approximate efficiency of 20%. (Exact tests are underway.)

[3] Feed stocks that pack densely such as rice husks and coffee hulls should be avoided because they do not fire well. All hays, stalks, and straws are great, as are branches pruned from orchard trees (best not more than 5 cm in diameter or they will not char through before the trench is full).

[4] https://en.wikipedia.org/wiki/Ultisol based on IUSS Working Group WRB (2015), World Reference Base for Soil Resources 2014, Update 2015, World Soil Resources Reports, 106, FAO, Rome.

[5] Participating farmers made their own biochar and biochar fertilizer. They applied it in one paddy and applied their normal NPK application in the immediately adjacent paddy. They and we observed rice growth for the season. At the end of the season, the two paddies we harvest and the yields compared. The farmers were happy about the better yield they got from the biochar. They ranked this third in importance after the benefits biochar provided to their soil and improved plant health. Watch video of interviews with farmers.

[2] This system has been tested by Warm Heart at our home facility and in Thai mountain corn fields. In December 2018 the director tested the system in North Ghana with subsistence farmers charring millet stalks. The trench did not smoke and ran at an approximate efficiency of 20%. (Exact tests are underway.)

[3] Feed stocks that pack densely such as rice husks and coffee hulls should be avoided because they do not fire well. All hays, stalks, and straws are great, as are branches pruned from orchard trees (best not more than 5 cm in diameter or they will not char through before the trench is full).

[4] https://en.wikipedia.org/wiki/Ultisol based on IUSS Working Group WRB (2015), World Reference Base for Soil Resources 2014, Update 2015, World Soil Resources Reports, 106, FAO, Rome.

[5] Participating farmers made their own biochar and biochar fertilizer. They applied it in one paddy and applied their normal NPK application in the immediately adjacent paddy. They and we observed rice growth for the season. At the end of the season, the two paddies we harvest and the yields compared. The farmers were happy about the better yield they got from the biochar. They ranked this third in importance after the benefits biochar provided to their soil and improved plant health. Watch video of interviews with farmers.